Egyedi gépek

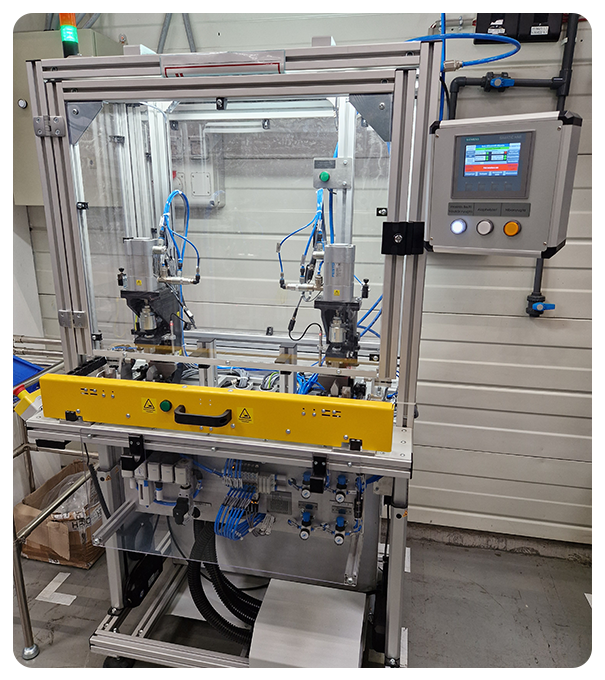

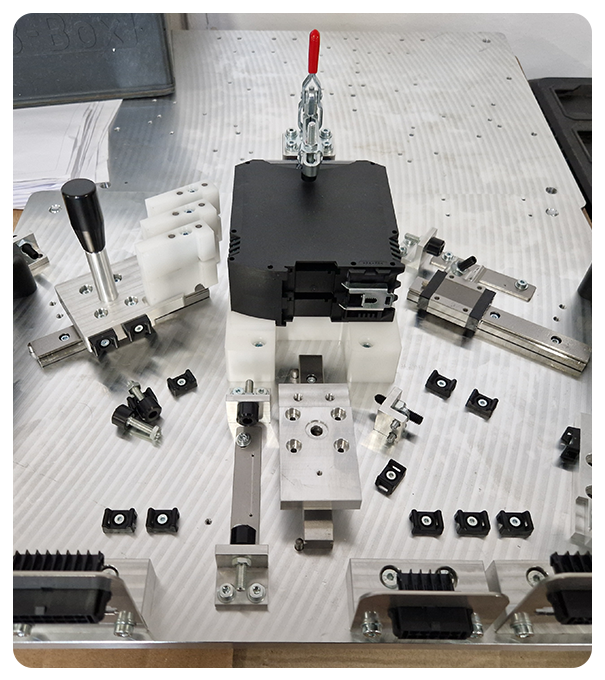

Our company’s main focus is the design, manufacturing, and commissioning of custom machines, special-purpose machines, and automated production cells.

We tailor every project to the unique needs of our clients, aiming to reduce production costs, accelerate manufacturing, minimize errors, and enhance product quality – all of which provide tangible market advantages for our partners.

Our custom special-purpose machines include assembly and sorting systems, inspection and optical control machines, leak testing and tightness inspection systems, tray loaders, material handling and logistics equipment, as well as conveyors – all designed to optimize in-process logistics and automated material flow.

All mechanical components, as well as electrical design and PLC programming, are carried out in-house, allowing our solutions to be fully tailored to the client’s processes and industry requirements. This approach enables us to provide efficient, customized solutions even for complex and challenging projects.

Széleskörű iparági tapasztalatunk révén ügyfeleink az autóipar, a medical és orvostechnikai szektor, a logisztikai rendszerek, az élelmiszeripar, a csomagolóipar, a gyógyszeripar, valamint a vegyipari és elektronikai gyártás területén is számíthatnak ránk . Mindenhol a komplett, testreszabott és magas színvonalú automatizálási megoldásokat kínáljuk, amelyek növelik a hatékonyságot és minimalizálják a leállásokat . A komplex gépgyártás mellett PLC programozásban is kimagasló szakértelemmel rendelkezünk, és Siemens, Omron vagy egyéb vezérlések integrálásával valósítunk meg összetett, nagy volumenű feladatokat is.

As a result, our partners can benefit from fully customized, efficient, and reliable automated systems, all developed in-house, providing genuine support for optimizing manufacturing processes.